Laser Cutting | Laser cutting – Tal.: 798 852 246

Metal cutting, sheet metal cutting, aluminum cutting, steel cutting, copper cutting, brass cutting.

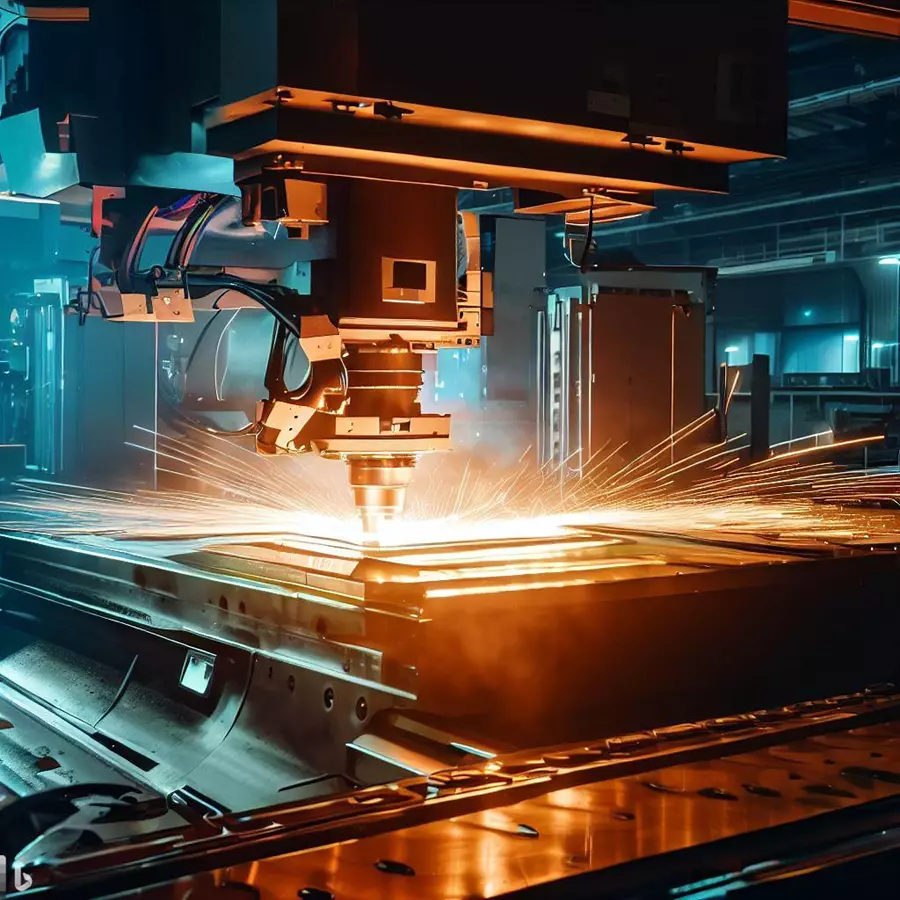

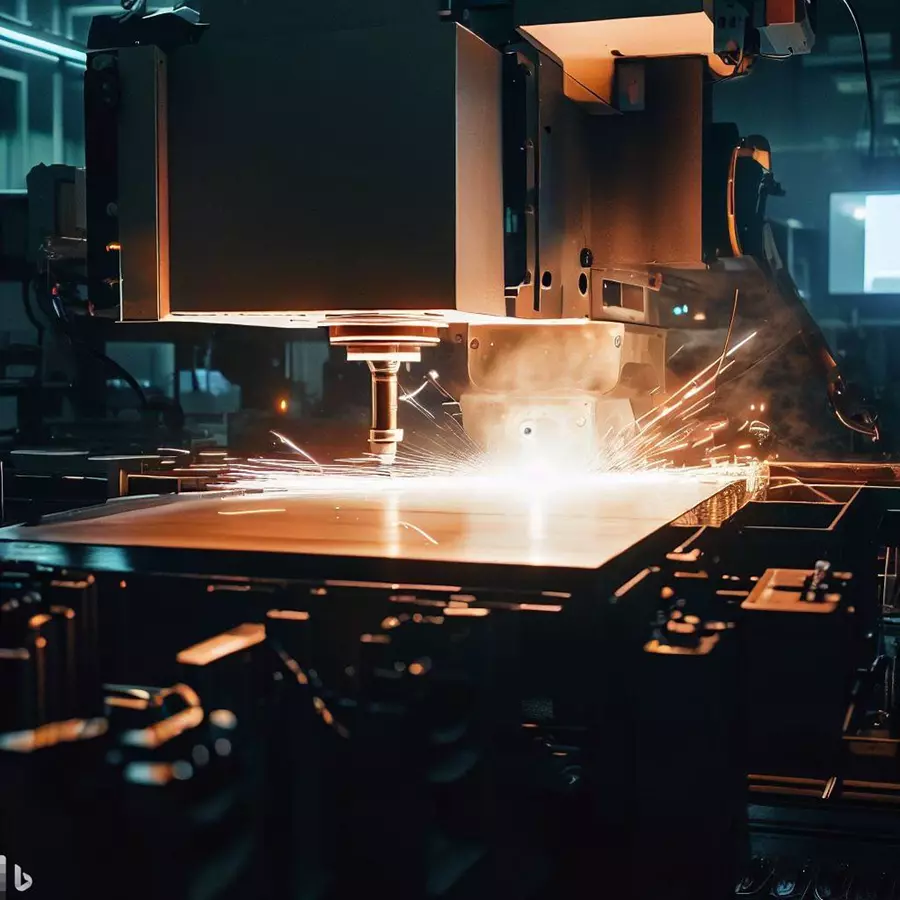

Laser Cutting Service

Order laser cutting – Tal.: 798 852 246 Laser cutting is a method of non-contact cutting of metal and non-metallic materials of various thicknesses. The basis of laser cutting is a combined, guided and formed laser beam. When the laser beam hits the workpiece, the material melts or evaporates. It is important that the full power of the laser is concentrated in one point with a diameter usually not exceeding half a millimeter. When more heat is concentrated at a given point than can be dissipated by heat conduction, the laser beam completely penetrates the material, initiating the cutting process.

The laser cutting process consists of several steps, each of which is important for achieving the expected results.

- Material preparation. The material to be cut must be properly prepared before the cutting process. In the case of metal, the surface must be cleaned of rust, oil or other contaminants.

- Laser programming. The laser operator programs the appropriate parameters such as laser power, laser travel speed and cutting shape. These settings depend on the type of material, thickness, and cutting pattern.

- Cut. After programming the laser, the operator starts the machine, which begins to cut through the material. During the laser cutting process, the moving laser is controlled by a computer system that accurately tracks the programmed cutting pattern.

- Quality control. After the cutting process is completed, the operator conducts a cut quality check to ensure that the cutting edges are smooth, clean, and in line with the requirements of the project.

- Post-machining. Depending on the requirements of the project, the cut edges may require additional processing, such as grinding or polishing.

- Waste disposal. Finally, material residues such as offcuts or waste must be removed from the surface of the material to be cut and from the inside of the machine.

The laser cutting process is automated and can be repeated, allowing materials to be cut quickly and precisely with minimal human labor.

- Precision. Laser cutting provides very high precision, which means that it is possible to accurately cut even the most complex designs. This process can produce highly accurate edges and finishes, which can be especially important for the production of highly complex components.

- Speed. Laser cutting is also very fast, so you can produce large quantities of components in a short time. Additionally, the process requires a minimum number of steps, which means that you can save time that would otherwise be spent having to use other cutting methods.

- No distortion. Laser cutting does not put pressure on the material, which means that there is no distortion or damage to the material that could affect its strength or quality. As a result, exact shapes can be obtained without the need for additional material processing.

- Multifunctionality. Lasers can cut a wide variety of materials, such as metal, wood, glass, plastics, fabrics, and more. This makes laser cutting very versatile and can be used in a variety of industries.

- Automation. Laser cutting can be automated, which means that the process can be controlled by a computer, thus eliminating the risk of human error. In addition, the automated process can run around the clock, which increases efficiency and saves time.

- Purity. Laser cutting is a clean process, which means that no waste is produced and the material is not contaminated by the cutting tools. In this way, you can obtain products with a very clean appearance and without the need for additional processing.

Laser cutting offers many advantages, such as high precision, speed, no distortion, multifunctionality, automation, and cleanliness, making it an attractive choice for many industries.

Laser is a very effective method of cutting metals because it can cut many types of metals with different thicknesses and densities.

- Carbon steel. The laser can cut carbon steel down to a few centimeters thick. It is the most widely used metal for laser cutting due to its widespread availability and low price.

- Stainless. The laser can cut stainless steel up to a few millimeters thick. Stainless steel is resistant to corrosion and is often used in the food, medical, and chemical industries.

- Aluminium. The laser can cut aluminum up to a few millimeters thick. Aluminum is a lightweight and durable metal that is often used in the aerospace and automotive industries.

- Copper. The laser can cut copper up to a few millimeters thick. Copper is a highly conductive metal and is used in the electrical and electronics industries.

- Brass. The laser can cut brass down to a few millimeters thick. Brass is resistant to corrosion and is often used in the watchmaking and electrical industries.

Each metal requires an individual approach to the cutting process, and also varies depending on the thickness and other characteristics. Therefore, before proceeding with laser cutting metal, it is important to tailor the process to the specific specification of the metal.

Laser cutting price – prices, price list 2024

The price of laser cutting can vary and depends on many factors. There is no definitive answer to the question of laser cutting price as it depends on the individual needs of the customer as well as the specifications of the project.

Factors that affect the price of laser cutting:

- Material. The price of laser cutting depends on the type of material to be cut. Some materials, such as stainless steel or titanium, are more expensive to cut than others, such as aluminum or wood.

- Material thickness. The price of laser cutting increases with the thickness of the material. Usually, laser cutting is more costly for thicker materials.

- Design complexity. The more complicated the design, the higher the price of laser cutting. Cutting more complex patterns requires more time and work, which affects the price.

- Cutting speed. Faster cutting means that more work can be done in less time, which affects the price of laser cutting. In some cases, there are additional fees for faster cutting rates.

- Number of elements. Often, cutting out more elements gives the benefit of a lower unit price.

Technologies used

Using more advanced laser cutting technologies can affect the cutting price.

The price of laser cutting depends on the specific situation. If you need a quote for laser cutting, please contact us at the e-mail address laser@gulajski.pl , or ask by phone about laser cutting price – tel. 798 852 246

Laser cutting offer

Using our laser cutting offer is a guarantee of quality, precision and saving time and money. Thanks to the use of this modern technology, we are able to offer you not only accurate cutting, but also a wide range of shapes and designs that we can cut from various materials.

You no longer have to worry about imperfections or mismatches of the cut material to your project.

Our laser cutting machine allows you to make accurate and clean cuts that are in line with the requirements of your project.

Additionally, laser cutting is faster and more effective than traditional cutting methods, allowing us to offer you competitive prices for our services.

We offer you rich experience and high-quality laser cutting services that are sure to meet your expectations. Trust us and take advantage of our offer, and you will certainly be satisfied with the results. Write to us at laser@gulajski.pl

We use modern technology that allows us to accurately cut and create a wide range of shapes and patterns from various materials. Our laser cutting machine enables you to make precise and clean cuts that are in line with your project requirements. Laser cutting is faster and more effective than traditional cutting methods, which allows us to offer competitive prices for our services.

We provide cutting services mainly for customers from the Silesian and Opole Voivodeships. Most often we cut materials delivered from the vicinity of cities:

- Silesian Voivodeship: Katowice, Częstochowa, Sosnowiec, Gliwice, Zabrze, Bytom, Bielsko-Biała, Ruda Śląska, Rybnik, Tychy, Dąbrowa Górnicza, Chorzów, Jaworzno.

- Opole Voivodeship: Opole, Kędzierzyn-Koźle, Nysa, Prudnik, Lubliniec, Brzeg.

Trust us and take advantage of our offer, and you will certainly be satisfied with the results. Feel free to contact us at laser@gulajski.pl.

In our production, we use laser cutting to cut metal details, which are key elements of our products.

Smoke dampers are one of the products for which we use laser cutting. Precise laser cutting allows you to obtain elements with non-standard shapes and dimensions, which are necessary to ensure a stable smoke damper structure. Thanks to laser cutting, we are able to obtain details with high accuracy and repeatability, which affects the durability and safety of our products.

Another application of laser cutting is in the structural elements of roof hatches. Laser cutting allows you to cut details with non-standard shapes and dimensions, which is essential for obtaining elements with high precision and repeatability. The elements obtained in this way are perfectly matched to the other structural elements, which affects the durability and safety of the entire product.

Laser cutting – Silesia and Opole region

Laser cutting, i.e. precise cutting of metal, is one of the key technologies that we use in our company. Thanks to it, we are able to produce precise elements of our products, such as handles, hinges or safety elements. Advanced laser cutting technology allows us to obtain details with high surface quality, which directly translates into the aesthetics and functionality of the final product.

The Gulajski company is proud to offer laser cutting and cutting services for customers from Silesia and the Opole region. We serve both large enterprises and individual clients from cities such as Katowice, Gliwice, Sosnowiec, Bytom, Zabrze, Opole, Rybnik, Tychy, Ruda Śląska and Kędzierzyn-Koźle. Our location and experience in the industry allow us to quickly and efficiently process orders, tailored to the individual needs of customers from these regions.

If you are looking for professional laser cutting services in Silesia or the Opole region, Gulajski is the perfect choice. We invite you to cooperation!

Laser cutting of sheet metal

Laser cutting of sheet metal is a modern metalworking technology that offers a number of advantages over traditional methods such as plasma or saw cutting.

Advantages of laser cutting:

- Precision: The laser provides extremely accurate cutting, which allows you to create details with complex shapes and high dimensional accuracy.

- High-quality edges: Laser-cut edges are smooth and do not require post-processing.

- Versatility: The laser can cut a wide range of materials, including steel, aluminum, copper, brass, and plastics.

- Efficiency: Laser cutting is a fast process, which allows you to process large amounts of material in a short time.

- Low emissions: Laser cutting is an eco-friendly process that generates minimal smoke and dust.

Laser cutting of sheet metal is used in many industries, m.in.:

- Automotive industry: Cutting body parts, mufflers, exhaust systems.

- Machinery industry: Cutting machine elements, tools, steel structures.

- Electronics industry: Cutting of enclosure components, printed circuit boards.

- Aerospace industry: Cutting structural elements of airplanes, helicopters.

- Construction: Cutting structural elements, facades, railings.

Laser cutting of steel

Laser cutting steel is an advanced material processing technology that uses a concentrated beam of laser light to precisely cut metal materials, including various grades of steel. It is a method characterized by high accuracy, efficiency and the ability to cut complex shapes with minimal material loss. This process is widely used in the machinery, automotive, construction and many other sectors requiring precision metal processing.

Laser cutting of steel is a technology that revolutionizes metalworking methods, offering manufacturers unparalleled precision, speed and flexibility in the implementation of even the most demanding projects.

Examples of laser cutting projects for customers from Silesia and Opole

Laser cutting Gliwice, 44-100 – Silesian Voivodeship – Laser Gliwice

A company from Gliwice, specializing in the production of car parts, contacted us in order to use laser cutting services. During the consultation, technical specifications, material requirements and expected lead times were discussed.

Based on the technical drawings provided, we prepared the corresponding files for the laser cutting machine. All data has been carefully checked to ensure precise cutting.

The laser cutting service helped the car company from Gliwice to produce precise and high-quality car parts, which contributed to the improvement of their production processes and customer satisfaction.

Laser cutting Silesia – Laser Silesia

A company from Silesia, specializing in the production of car parts, contacted us in order to use laser cutting services. During the consultation, technical specifications, material requirements and expected lead times were discussed. Based on the technical drawings provided, we have prepared suitable files for the laser cutting machine. All data has been carefully checked to ensure precise cutting. Laser cutting service helped a car company from Silesia to produce precise and high-quality car parts, which contributed to the improvement of their production processes and customer satisfaction.

Laser cutting Tarnowskie Góry, 42-600 – Silesian Voivodeship – Laser Tarnowskie Góry

A company producing exclusive metal fences from Tarnowskie Góry contacted us as a company providing laser cutting services. During the consultation, technical specifications, material requirements and expected lead times were discussed.

Once the design was approved, the laser cutting process began. Advanced laser cutting machines are used, which guarantee high precision and repeatability. Materials such as stainless steel have been precisely cut as required.

This laser cutting service has helped the company from Tarnowskie Góry to produce precise and high-quality fencing components, which has contributed to improving their production processes and customer satisfaction.

Laser cutting Zabrze, 41-800 – Silesian Voivodeship – Laser Zabrze

A manufacturer of exclusive metal fences from Zabrze has established contact with our company, specializing in laser cutting services. During the consultations, we discussed in detail the technical specifications, requirements for the materials used and set deadlines. Once the design was approved, we started the laser cutting process. We have used advanced machines for this purpose, which ensure exceptional precision and repeatability of the process. Materials such as stainless steel have been precisely cut according to specific requirements. Our laser cutting service has significantly contributed to the production of accurate and high-quality fencing elements for a company from Zabrze. As a result, their production processes have been streamlined and customer satisfaction has increased.

Laser cutting Lubliniec, 42-700 – Opole Voivodeship – Laser Opole

A corporation producing furniture from quartz sinters has established contact with our company. During the meeting, technical specifications, requirements for raw materials and expected deadlines were discussed.

After the cutting process was completed, all components went through rigorous quality control. Each fragment was checked for precision, dimensions and surface quality, after which the elements were delivered to the company’s headquarters in Lubliniec.

This laser cutting service has helped a quartz sintered furniture company to produce precise and high-quality furniture components, which has contributed to improving their production processes and customer satisfaction.

Laser cutting Pyskowice, 44-120 – Silesian Voivodeship – Laser Gliwice

A company specializing in the production of furniture in Pyskowice from quartz composites has established contact with our company. During our meeting in Pyskowice, we discussed in detail the technical specifications, requirements for raw materials and set the expected deadlines.

After the cutting process was completed, all components went through rigorous quality control. Each fragment has been carefully evaluated in terms of dimensional precision and surface quality. Then we delivered these elements to the company’s headquarters in Pyskowice.

Thanks to our laser cutting service, a company from Pyskowice dealing with the production of furniture from quartz composites has gained the ability to create precise and high-quality furniture elements. This, in turn, has helped to improve their production processes and increase customer satisfaction.

Our Guides

CNC PRESS BRAKE – SERVICES

Bending machines, especially those that use a hydraulic drive, are designed to physically and accurately model the raw material, often sheets of a variety of raw materials. Although their foundations of operation are trivial (they are based on the modification of the...

Types of flat roofs

Flat roofs are commonly found in a variety of types of structures. However, the decision to choose a flat roof for a particular building requires consideration. They are different from the more aesthetic pitched roofs that we often see in single-family houses and...

Polycarbonate CNC Machining

Polycarbonate, also known as PC, is an amorphous thermoplastic that softens before reaching its melting point. It is characterized by transparency, impact resistance, strength and lighter weight compared to glass, which makes it an excellent alternative to this...